Reprocessing your plastic with Pulse Plastics helps you to develop a circular economy that reduces your material costs and moves your business towards eradicating plastic waste.

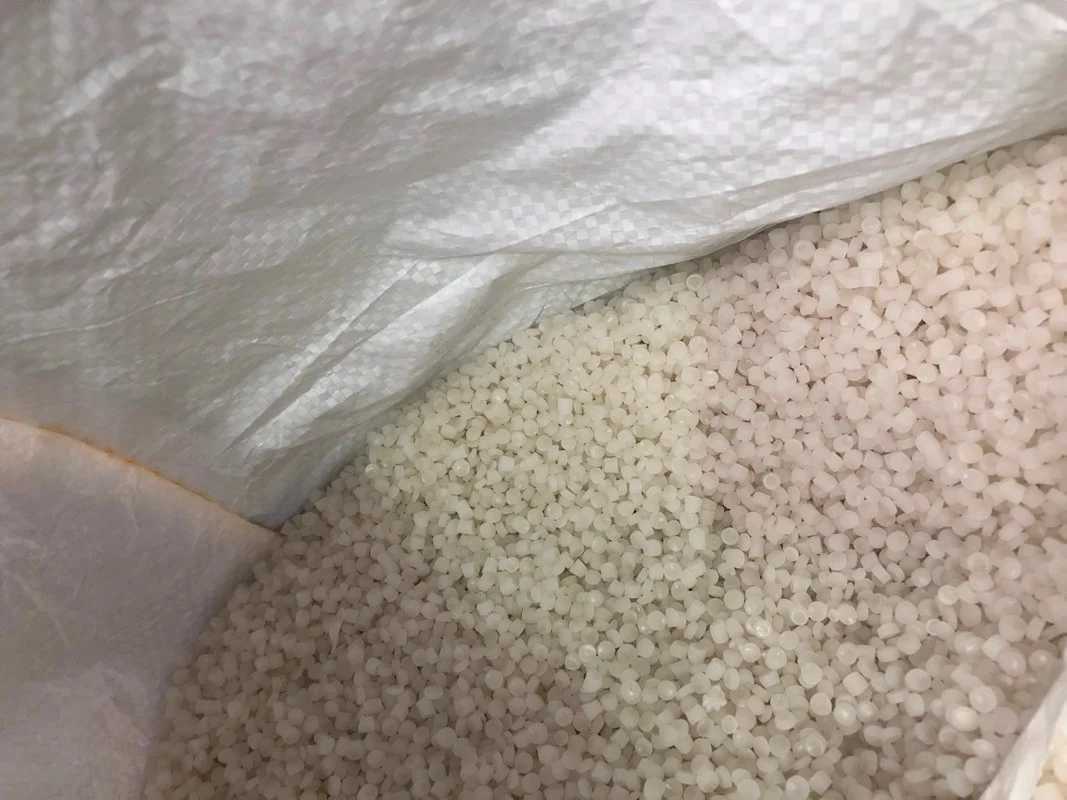

Convert waste plastic into a reusable, possibly bespoke, plastic pellet that can be used in your manufacturing process time and time again.

Stop sending your plastic waste to landfill. Start saving money and reduce your impact on the environment.

Get in touch

Plastic Reprocessing is an innovative solution to recover, reprocess and reuse post-industrial plastic waste.

Pulse Plastics reprocessing involves the conversion of waste Polyethylene (PE), High Density Polyethylene (HDPE), Low Density Polyethylene (LDPE) and Polypropylene (PP) into a reusable pellet that can be used in your manufacturing process.

Pulse Plastics can offer pellet grades for general purpose or specialist production processes, which may need specific Melt Flow Index (MFI) or high tensile strength.

We are converting post-consumer, post-industrial plastic waste (PE, PP), (Film, Flake) into a uniform pellet that can be used for plastic production other than where finished product is not intended for the food industry.

Pulse Plastics has a number of strand-lines and pelletising machines that are able to work for customers new and old on a bespoke basis.

Speak to the team today to learn how Pulse Plastics can help your business save money, become more sustainable and create a circular economy for you.

The pelletised product can be produced bespoke to your needs.

Pulse Plastics has a number of strand-lines and pelletising machines that are able to work for customers new and old.

We understand that you may have some questions about plastic reprocessing. We are here to help.

Pulse Plastics , currently has 4 machines that can each reprocess up to 25 tons a week. We can process film or flake into pellet, this can be Polypropylene(PP) or Polyethylene (PE).

Yes, this can happen, but a discussion surrounding the level of mix would need to take place. Please contact us and have that conversation.

No, but reprocessed plastic is obviously not the same quality as virgin plastic.

Let’s have a chat to see how we can help your business and your plastic needs.

We are here to help answer your questions. Talk to us today about your plastics solution needs.